Welcome to Qingdao Dashang Metal Co.,Ltd!

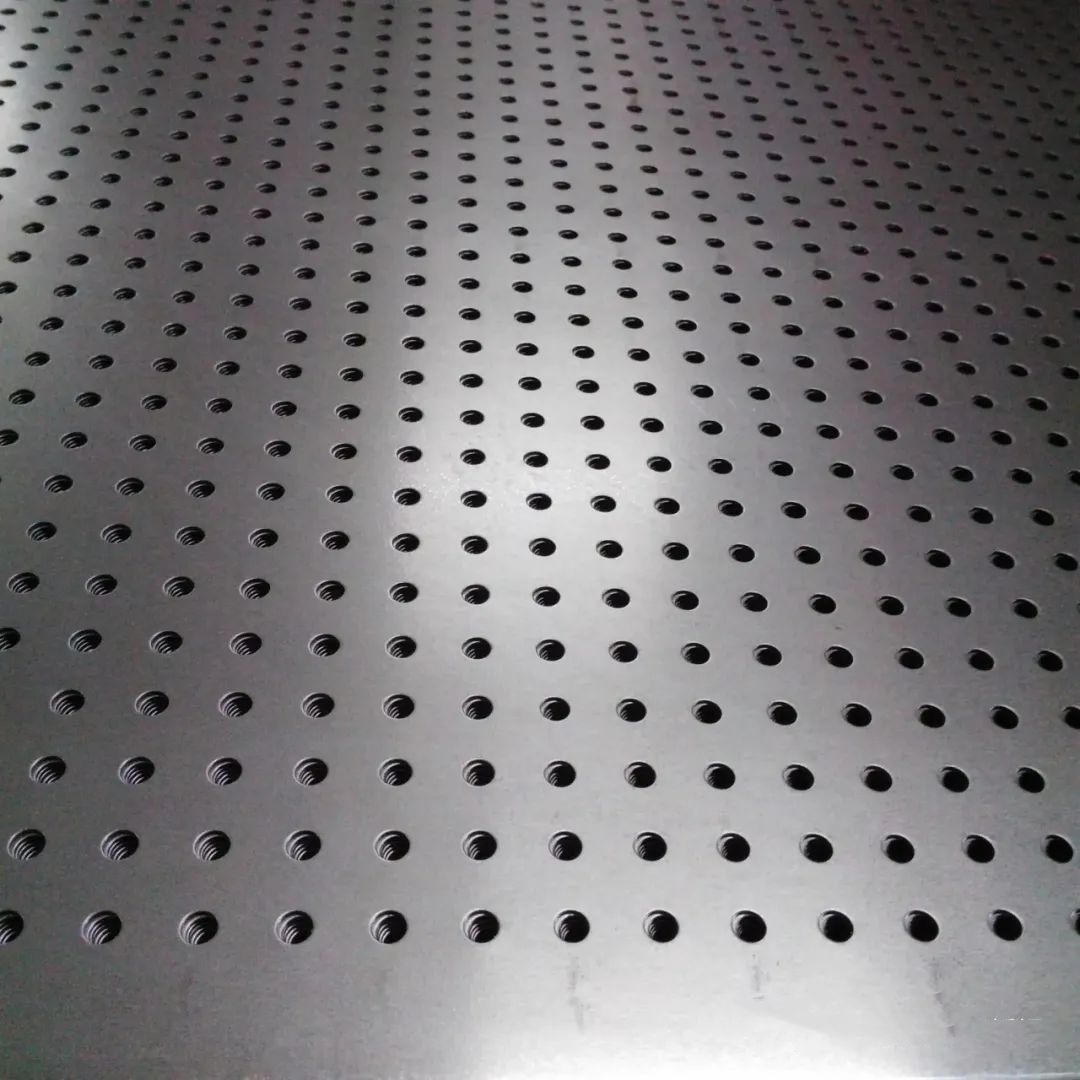

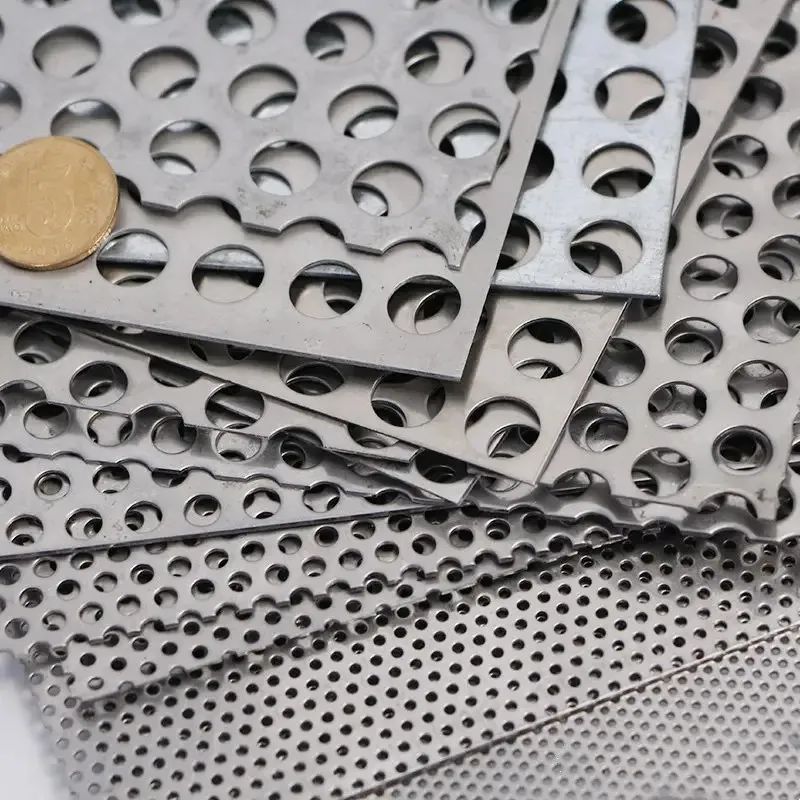

Stainless steel punching plate is a kind of mesh plate produced by continuous punching of stainless steel plate on a numerical control punch. It is widely used in various fields. Some stainless steel punching plates will be deformed after production.

There are four main aspects that affect the flatness of stainless steel punching plate:

1. Plate material: common materials such as 201, 304, 316 and 430 are often used for stainless steel plates. These stainless steel plates have rigidity and toughness, and the deformation degree is greater than that of other metal plates. Therefore, deformation phenomenon generally exists after they are made.

2. Die wear of stamping equipment: the die will wear during use. If the wear is severe and still in use, it will increase the deformation of stainless steel punching plate and increase the difficulty of leveling.

3. Reserved edge of plate: the larger the reserved edge of stainless steel punching plate, the worse the flatness. Especially for the plate with large aperture ratio and large aperture, the deformation with large margin will be serious.

4. Aperture spacing of mesh: the smaller the aperture of mesh and the closer the spacing, the greater the deformation of stainless steel punching plate. The numerical control punching process is equivalent to annealing the stainless steel plate, so the stainless steel punching plate will become hard and uneven.

The stainless steel punching plate will be leveled after processing.