Welcome to Qingdao Dashang Metal Co.,Ltd!

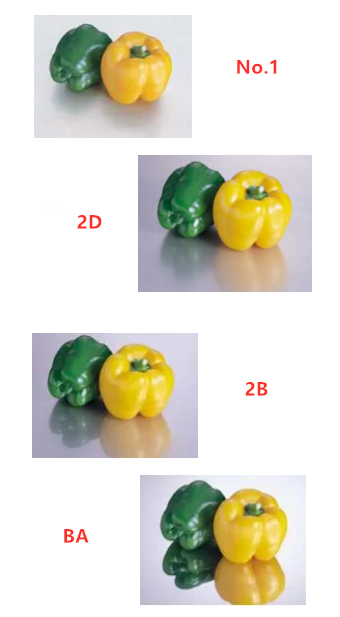

The main difference is the surface smoothness: the smoothness of the 2D surface is lower than that of the 2B surface

Purpose: 2D surface stainless steel is widely used in two aspects of "deep stamping and spraying":

For workpieces that require deep stamping, because the surface is not smooth, it is easy to retain lubricant on the surface of the steel plate during stamping, and improve the quality of deep drawing processing. If there is a requirement for brightness on the surface, it needs to be polished after molding.

Workpieces that need to be sprayed, because the adhesion of the coating on the rough surface is much better than that of the 2B surface. This is widely used in container manufacturing. At present, the 2D surface of 409L and 410L stainless steel is widely used in the container manufacturing industry. . Compared with the common 2B surface, the smoothness of the 2D surface is lower than that of the 2B surface, but the overall surface is still very uniform and matt. The 2D surface is generally heat treated and pickled after cold rolling, and then smoothed with a mat roll.

Address : N0103 Yanyang road chengyang district Qingdao city Shandong

Tel : 0086-532-87966227

Web: http://dashangjinshu.en.alibaba.com

E-mail: eric@dashangmetal.com

Copyright © 2019 Qingdao Dashang metal Co.,Ltd. ![]() Powered by HiCheng

Powered by HiCheng