Welcome to Qingdao Dashang Metal Co.,Ltd!

316 stainless steel has the advantages of super high temperature resistance, super corrosion resistance, super high strength, super easy processing, etc. What is the difference between 316 and 316L?

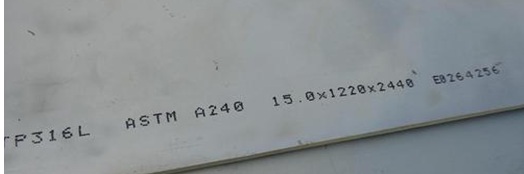

The Ni content of AISI316L (ASTM) is 10-14%, and the Ni content of SUS316L (JIS) is 12-15%. According to the minimum standard, ASTM and JIS have a 2% difference in Ni content, and their prices are different. It is necessary to identify when purchasing 316L products, whether the products refer to ASTM or JIS standards.

At present, there are very few 316 stainless steels on the market. The upper limit of C content of 316 is 0.08%, and the upper limit of C content of 316L is 0.03%.

As the current refining technology is very mature, steel mills can reduce the C content very well. Therefore, steel mills generally only produce 316L. Due to the low demand for 316, 316 needs to be ordered from the steel mill in advance.

316 and 316L differ in performance due to the difference in C content. The higher the C content, the easier it is to cause intergranular corrosion, such as during welding. Higher C content will also increase the tensile and yield strength of 316. The lower limits of tensile and yield strength of 316 are 515 and 205 MPa, respectively, and the lower limits of tensile and yield strength of 316L are 485 and 170 MPa, respectively.

316L is a derivative steel of 316 stainless steel, with 2 to 3% Mo element added. On the basis of 316L, many steel grades are also derived. For example, 316Ti is derived from adding a small amount of Ti, 316N is derived from adding a small amount of N, and 317L is derived from increasing the content of Ni and Mo. Most of the existing 316L on the market is produced in accordance with American standards. For cost considerations, steel mills generally keep the Ni content of their products as low as possible. 316L has a wide range of applications in the chemical industry due to its excellent corrosion resistance