Welcome to Qingdao Dashang Metal Co.,Ltd!

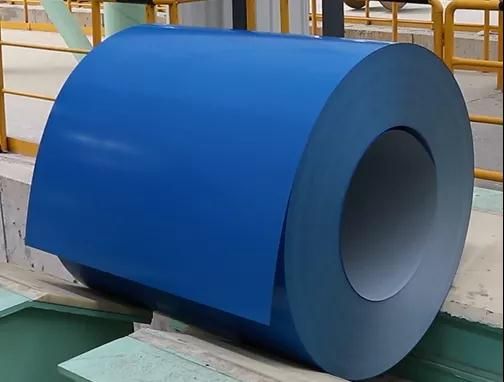

The selection of color coated steel sheet (PPGI) needs to consider the mechanical properties of steel sheet, substrate type, coating thickness and coating performance. Only in this way can we choose the right product

1、 Selection of mechanical properties

The mechanical properties are mainly selected according to the use, processing method and deformation degree. When the strength requirement is not high and the deformation is not complicated, the color coated steel sheet of TDC51d and TDC52d series can be used. TDC53d and TDC54d series color coated steel plates should be selected when there are higher requirements for formability. For members with load-bearing requirements, appropriate steel plates should be selected according to the design requirements, such as TS280GD and TS350GD series color coated steel plates. The mechanical properties may also change with the increase of storage time.

2、 Selection of substrate type and coating weight

The substrate type and coating thickness are mainly selected according to the use, corrosion of service environment, service life and durability. The substrate type and coating thickness are the main factors affecting the corrosion resistance of color coated steel sheet. Generally, the color coated steel sheet is hot-dip galvanized steel sheet(GI) and hot-dip aluminum zinc steel sheet(SGLC), which have better corrosion resistance. Electro-galvanized steel sheetDue to the process limitation, the zinc coating is usually thin, the corrosion resistance is relatively poor, and the production cost is high, so it is rarely used.

The coating thickness should be determined according to the corrosivity of the service environment, and the steel plate with large coating thickness should be used in the environment with high corrosivity. The difference of corrosion resistance of various steel plates should also be paid attention to when selecting steel sheet.